Hello everyone, [GS-JJ]’s new section: “The Craftwork Class of Custom Pins” started!

Here, we will popularize the knowledge point about custom pins every week that help you understand custom lapel pins more deeply and provide help to our customers.

Today’s first episode, let’s talk about the offset printed and silkscreen process of custom lapel pins.

The two custom pins in the picture above, can you tell which one used offset printed and which one used silkscreen? If you can tell, congratulations, you are professional. It doesn’t matter if you don’t know. Our craftwork class will let you know them.

Offset printed and silkscreen is all printing processes, but their printing methods and functions are different. We will introduce in detail the process and characteristics of the two below.

Offset Printed

Offset printing also known as the whole printing can be printed in a variety of complex colors and patterns.

The characteristics of offset printed:

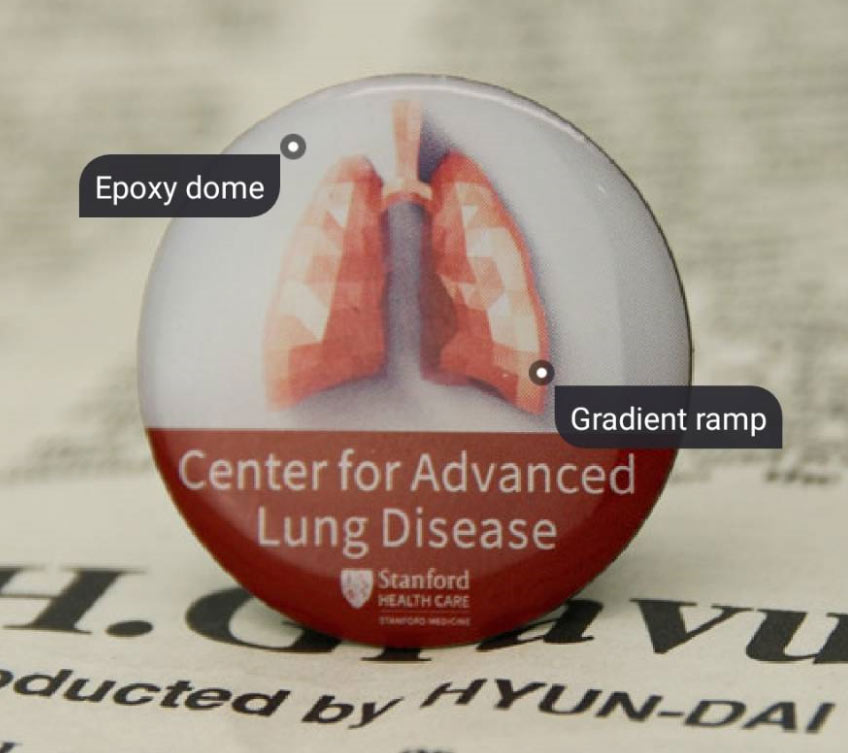

- Showing a gradual color change.

- There is no need for raised metal areas to divide different color areas.

- Custom sizes and shapes are available, fonts and colors have no restrictions

- Offset printing usually requires the addition of epoxy protection colors of custom lapel pins.

Silkscreen

Silkscreen is the use of the screen, through the photoengraving technology to the lapel pins printed text and patterns. It is mainly for simple graphics, less color, small patterns, and texts.

The features of screen printing:

- The silkscreen process can be used to make a lapel pin independently. If there are small texts or patterns on the soft enamel pins or hard enamel pins that cannot be made with molds, silk screen printing will be used instead and the effect of the pins will not be affected.

- No raised metal areas to divide different colors and no gradient pattern.

Offset Printed VS Silkscreen

- Offset printing can print out complex photos or colors. The strength of silkscreen is to clearly reflect small texts.

- Offset printing can only be mixed with the epoxy process while silkscreen can be mixed with the process of soft enamel, hard enamel, and epoxy.

Silkscreen VS Enamel Craft

The custom pins that silkscreen mixes with the enamel process are very common, but many people don’t know the differences between them.

- Silkscreen has no metal lines. Enamel craft is to use the metal line-divided paint areas.

- Silkscreen can clearly reflect small texts and small texts using enamel craftsmanship will not be clearly reflected, that means silkscreen can be as an aided process (this is why we often see the silkscreen process added to enamel pins)

Offset Printed VS Enamel Craft

In order to let everyone a more thorough understanding of the custom lapel pins craft, we will also compare the difference between offset printed and enamel craftsmanship.

- Offset printing is no metal division area and the surface is smooth. The enamel process is bumpy, soft enamel has noticeable embossing and hard enamel need finger touch to feel the unevenness of the surface.

- Offset printed can perfectly reflect the gradation colors of photos and landscapes. The enamel crafts need metal to divide colors. For more details on the enamel process, please check out this link: https://www.gs-jj.com/blog/soft-enamel-vs-hard-enamel-pins/

Today’s craftwork class is over. Have you learned about offset printed and silkscreen? If you have any other questions, you can leave messages in our comment area. Customize offset printed pins or silkscreen custom enamel pins, please go to: you can place an order.